Introduction

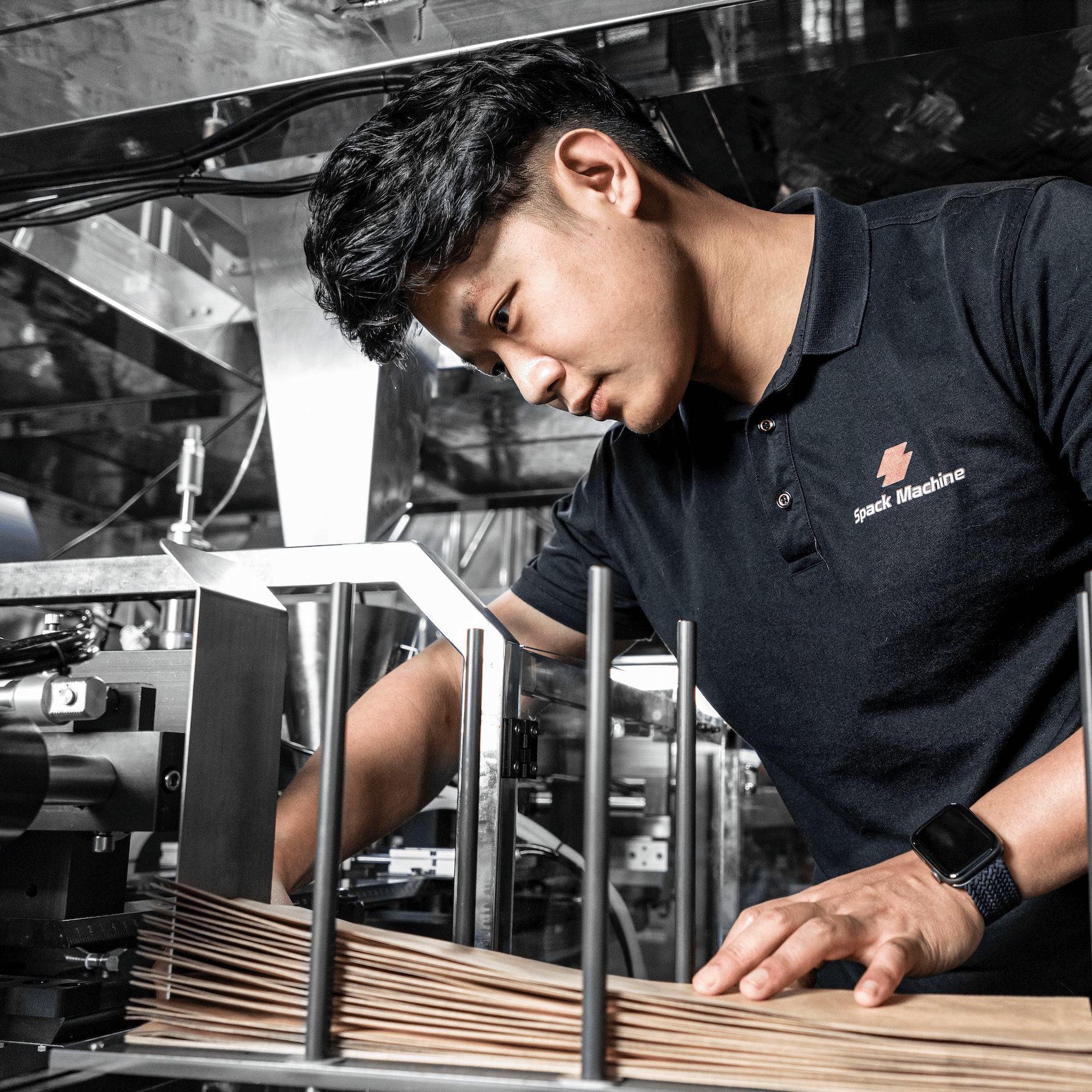

Ever wondered why that tiny ketchup packet or skincare sample feels so perfectly portioned? That’s the magic of sachets—small but mighty players in the packaging world. As someone who’s spent a decade diving deep into packaging solutions with a Mechatronics degree in my back pocket, I can tell you there’s more to these little packets than meets the eye. At SpackMachine, we’ve built our reputation on crafting machinery that turns these concepts into reality for businesses like yours.

What are sachets, exactly? They’re not just convenient; they’re a game-changer for industries like food, cosmetics, and pharmaceuticals, offering precision and portability in a single-use design. In this guide, I’ll walk you through their definition, their surprisingly practical origins, and how they stack up against stick packs—a comparison that could shift your packaging strategy. Whether you’re a manufacturer or a business owner, you’ll find actionable insights to make smarter decisions.

Stick with me as we unpack the versatility of sachets, explore their real-world applications, and break down why partnering with reliable suppliers like SpackMachine can elevate your production game.

What Are Sachets? Unpacking the Basics

When examining modern packaging solutions, understanding what are sachets becomes essential for brands seeking efficient, single-use options. Sachets represent one of the most versatile packaging formats that have evolved significantly throughout history while maintaining their core purpose of containing small amounts of products.

Sachet Definition: What Makes a Sachet Unique?

A sachet definition at its most basic is a small sealed packet containing a single serving or application of a product. These small, flexible pouches typically hold between 1-10ml of content and are designed for one-time use. What distinguishes sachets from other packaging formats is their compact size, convenience, and ability to preserve product freshness through hermetic sealing.

Defining Characteristics of Modern Sachets

Modern sachets feature several key characteristics that define their functionality and appeal across industries:

| Feature | Description | Benefit |

|---|---|---|

| Size | Typically 2-4 inches in dimension | Portable and space-efficient |

| Sealing | Three or four-side seals | Prevents contamination and extends shelf life |

| Material Structure | Multi-layer laminates | Provides barrier protection against moisture, light, and oxygen |

| Opening Mechanism | Tear notches or easy-tear features | Enhances user experience |

| Customizability | Printable surfaces | Brand visibility and regulatory compliance |

Historical Roots: From Scented Pouches to Practical Packaging

The history of sachets dates back centuries, originating as small cloth bags containing aromatic herbs and spices. These early sachets were primarily used for perfumery and medicinal purposes in ancient civilizations. By the 18th century, scented sachets became popular in Europe for freshening linens and clothes.

Evolution of Sachet Usage Through History

The transition from decorative scent pouches to practical packaging design solutions began during the industrial revolution. The introduction of food preservation techniques and mass production created a need for portion-controlled, sealed packages. By the mid-20th century, sachets had evolved into the flexible packaging format we recognize today, supporting the growing consumer demand for convenience and portability.

Modern Evolution: Materials and Design Innovations

Understanding what are sachets today requires examining the significant advances in materials and manufacturing technology. Modern sachets typically employ multiple material layers, each serving a specific function:

How Are Sachets Made and What Materials Are Used?

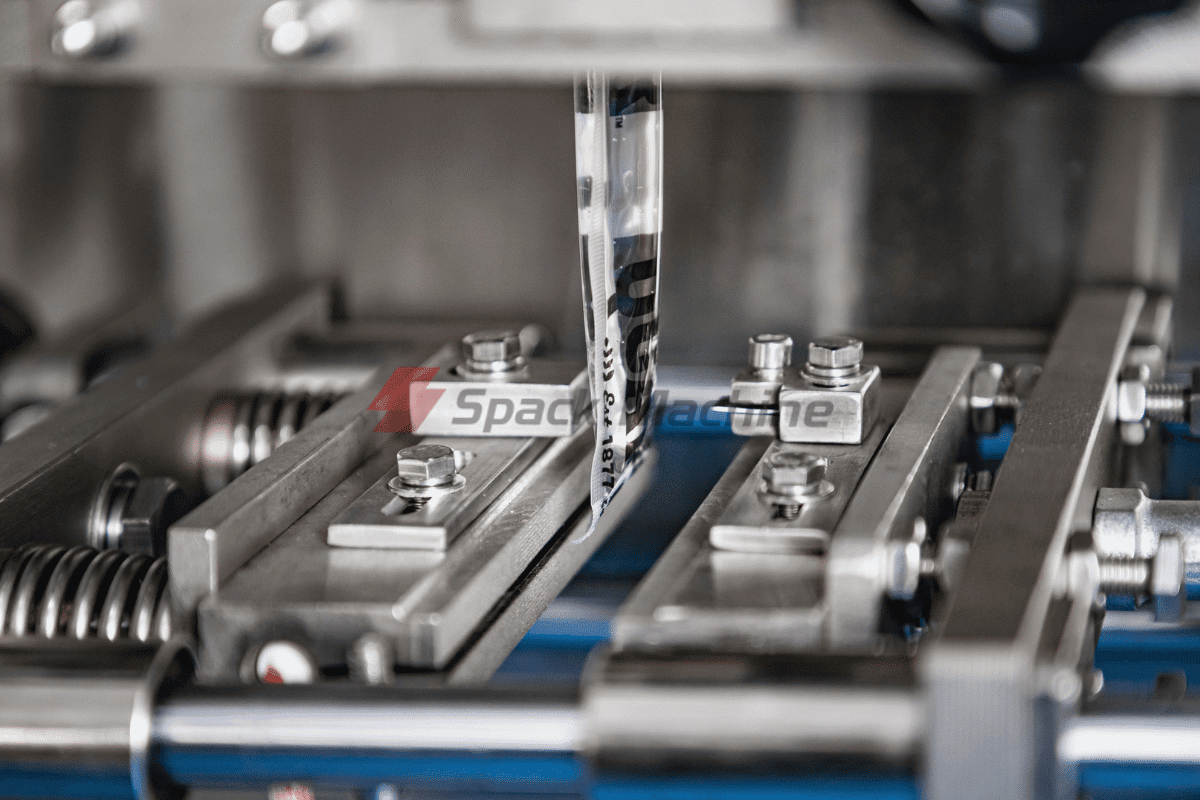

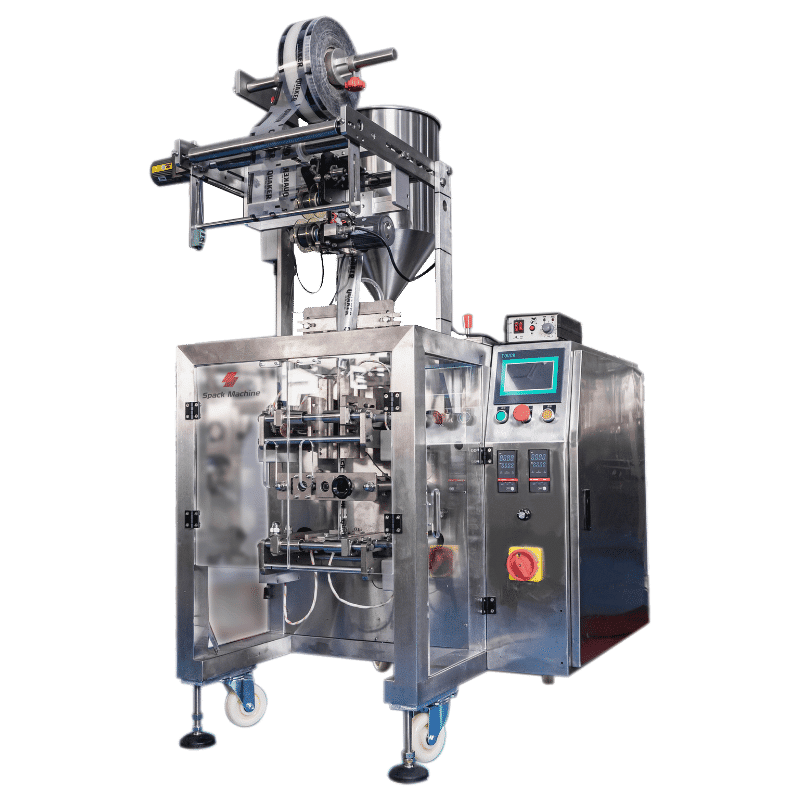

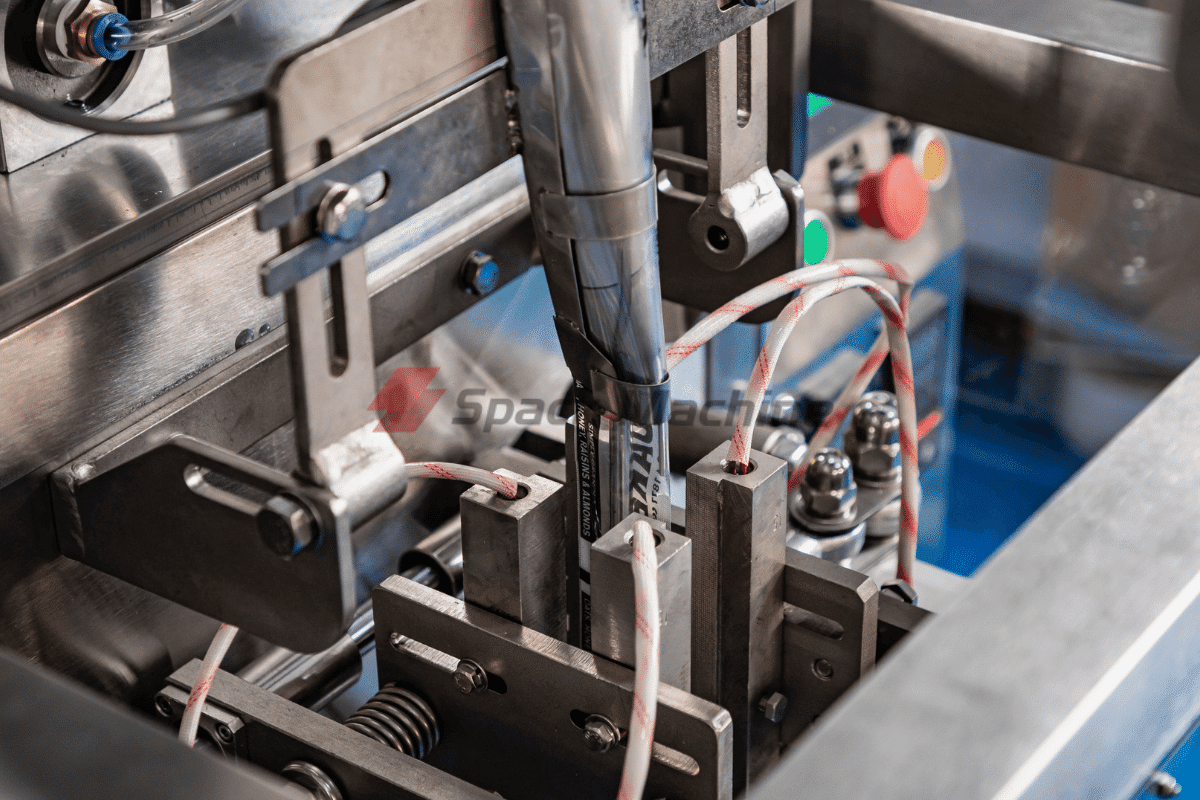

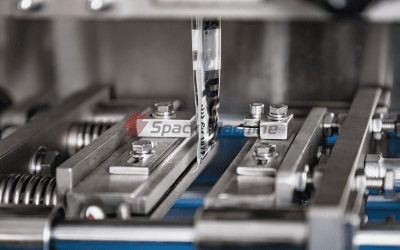

Contemporary sachets usually feature a laminated structure combining various materials like polyethylene, aluminum foil, and polyester. This multi-layer approach creates barriers against environmental factors that could compromise product integrity. High-speed production equipment, like those manufactured by SpackMachine with CE- and FDA-certification, has revolutionized sachet production, enabling outputs of hundreds of units per minute with precise filling and sealing capabilities.

Why Sachets Matter in Today’s Packaging Landscape

Sachets have become indispensable across numerous industries due to their versatility and efficiency. From cosmetics and pharmaceuticals to food and beverages, single-use packets provide significant advantages in terms of product preservation, dosage control, and consumer convenience.

What Are the Different Types of Sachets?

The sachet category encompasses various formats designed for specific applications. Wet sachets containing liquids or gels utilize different barrier properties than dry sachets for powders or granules. While sachets and stick packs may appear similar, they differ significantly in design, filling processes, and user experience. Stick packs typically feature a tubular shape optimized for powders, while sachets offer more flexibility in shape and content types.

This distinction between sachets and stick packs represents an important consideration for brands selecting the optimal packaging format for their products, affecting not just functionality but also production costs and consumer perception.

Types of Sachets and Their Design Features

Understanding what are sachets in terms of their structural variations is crucial for selecting the right packaging solution for your products. Sachets come in multiple designs, each engineered for specific applications and contents, from dry powders to viscous liquids.

Flat Sachets: Ideal for Powders and Creams

Flat sachets represent one of the most common sachet packaging applications in industries requiring precise dosing and compact storage. These sachets feature two panels sealed on all four sides, creating a flat profile that maximizes shelf efficiency and minimizes material usage.

Design Characteristics of Flat Sachets

The defining feature of flat sachets is their minimal headspace, making them particularly suitable for dry products. Their planar geometry provides excellent printable surface area for branding while maintaining a slim profile. The four-side seal configuration creates strong barrier properties, extending product shelf life significantly compared to traditional packaging formats.

| Sachet Type | Ideal Contents | Typical Capacity | Key Advantages |

|---|---|---|---|

| Flat Sachets | Powders, Tablets, Thin Creams | 1-10g | Space-efficient, Maximum Print Area |

| Pillow Sachets | Liquids, Gels, Granules | 3-30ml | Volume Flexibility, Production Speed |

| 3-Side Seal Sachets | Semi-solids, Thicker Creams | 5-20ml | Easy Dispensing, Controlled Flow |

| Shaped Sachets | Premium Products, Specialized Items | Varies | Brand Differentiation, Enhanced User Experience |

Pillow Sachets: Flexible and Widely Used

Pillow sachets derive their name from their distinctive puffy appearance, created by a continuous tube of material sealed at intervals. This design forms one of the most versatile small packet packaging options available today, accommodating a wide range of product viscosities.

Applications and Benefits of Pillow Sachets

The expanded internal volume of pillow sachets makes them ideal for liquid products that require more space than flat sachets can provide. Their shape facilitates easier dispensing for consumers while offering manufacturing advantages through continuous form-fill-seal production processes. These sachets are commonly used for shampoo samples, condiments, and liquid pharmaceuticals.

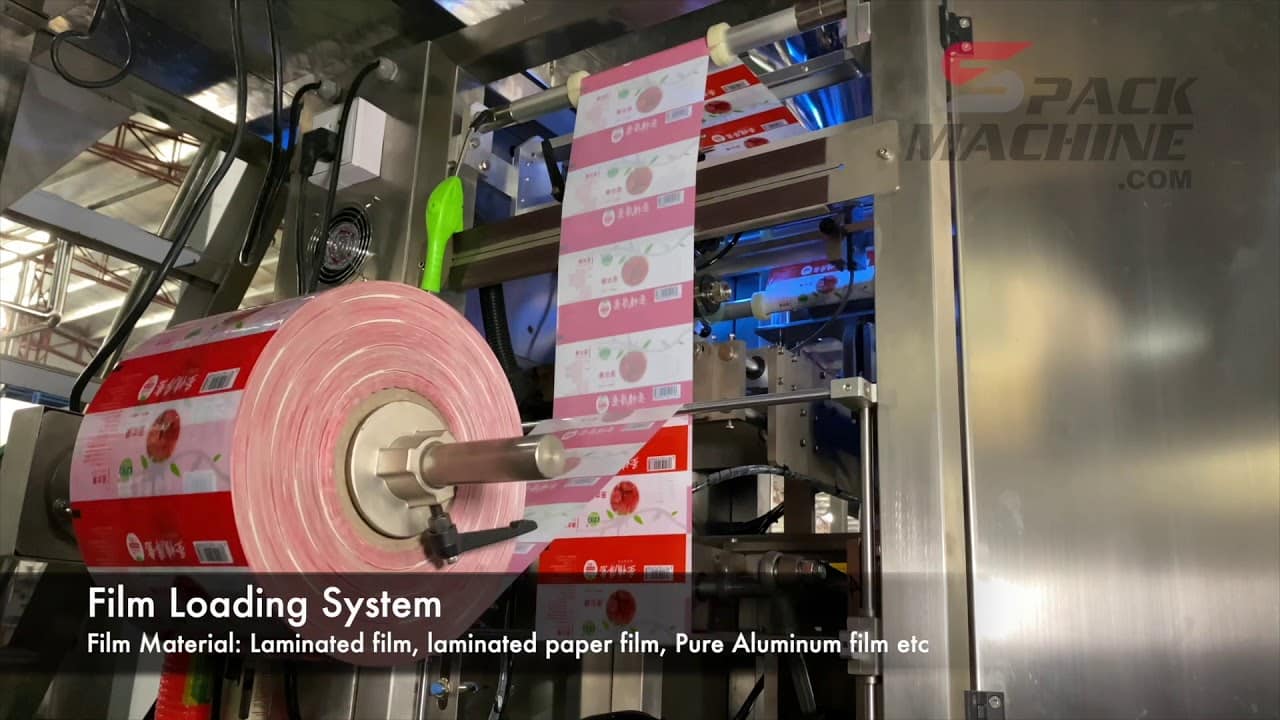

Material Breakdown: Foil, Plastic, and Paper Layers

Modern sachets typically employ multi-layer laminated structures to create effective barriers against environmental factors. Understanding what are the different types of sachets requires examining their material composition, which varies based on product requirements.

How Material Selection Impacts Product Protection

The outer layer, typically polyester or paper, provides printability and physical strength. The middle layer, often aluminum foil, creates barriers against light, oxygen, and moisture. The inner layer, usually polyethylene or polypropylene, enables heat-sealing and ensures product compatibility. This strategic layering is essential for sachet applications in cosmetics and food packaging, where product integrity is paramount.

Customization Options: Shapes, Sizes, and Branding Space

Beyond standard configurations, sachets offer extensive customization possibilities. SpackMachine’s sachet packaging equipment enables businesses to create distinctive packaging that aligns with brand identity while meeting product-specific requirements.

Industry-Specific Customization Requirements

Pharmaceutical sachets often feature child-resistant designs and tamper-evident seals. Cosmetic sachets might incorporate specialized dispensing features or premium finishing options. Food sachets require food-grade materials and may include easy-tear notches for improved user experience. The versatility of modern sachet production equipment allows for these adaptations without sacrificing production efficiency.

When comparing sachets to stick packs, it’s worth noting that sachets typically offer more design flexibility and shape options, while stick packs excel in dispensing precision for powdered products. This distinction helps brands select the optimal format based on both product characteristics and consumer usage scenarios.

Sachets vs Stick Packs: A Detailed Comparison

When considering single-use packaging options, understanding what are sachets compared to stick packs becomes crucial for making informed decisions. Though often confused with each other, these two formats have distinct characteristics that make each better suited for specific applications.

Design Differences: Flat Squares vs Slim Tubes

The most obvious distinction between sachets and stick packs lies in their physical design. Sachets typically feature a square or rectangular shape with four-sided seals, while stick packs are characterized by their elongated, slim tubular design. This fundamental difference affects everything from production methods to user experience.

Key Design Specifications Compared

| Feature | Sachets | Stick Packs |

|---|---|---|

| Typical Dimensions | 2-4 inches square/rectangular | 4-8 inches length, 0.75-1.5 inches width |

| Seal Configuration | 3 or 4-side seals | Back seal with top/bottom cross seals |

| Volume Capacity | 1-30ml | 3-15g (primarily for powders) |

| Shape Versatility | High (custom shapes possible) | Limited (primarily straight tubes) |

| Filling Speed | Moderate to High | Very High |

Functionality: Best Uses for Powders, Liquids, and Granules

The sachet benefits become most apparent when packaging semi-liquid products like creams, gels, and pastes, offering excellent containment and dispensing. Stick packs, however, excel with free-flowing dry products like powdered beverages, supplements, and granular substances.

Content Compatibility Considerations

The narrow profile of stick packs creates a controlled pouring channel that significantly reduces spillage of powders. In contrast, sachets provide broader dispensing surfaces ideal for viscous products. This distinction helps explain how do sachets compare to stick packs in practical applications – sachets offer versatility across product types, while stick packs provide precision for specific products.

Cost Analysis: Production Efficiency and Material Use

When evaluating sachet vs stick packs in terms of cost and convenience, production factors play a significant role. Stick pack machines typically achieve higher production speeds, often producing 30-50% more units per hour than comparable sachet equipment. However, this efficiency must be balanced against application-specific needs.

Efficiency Factors in High-Volume Production

Stick packs generally use less packaging material per unit, reducing raw material costs for high-volume production. Conversely, sachets may require more material but offer greater flexibility in product types and volumes. SpackMachine’s production equipment for both formats enables manufacturers to optimize this balance based on specific product requirements and market demands.

Branding Potential: Surface Area and Consumer Appeal

The packaging design considerations extend beyond functionality to marketing impact. Sachets provide larger printable surface areas for branding, product information, and regulatory compliance. Stick packs, while offering less space, create distinctive shelf presence through their uniform, premium appearance.

Customer Interaction and User Experience

Consumer interaction differs significantly between formats. Stick packs offer a controlled, directional pour that suits precision applications. Sachets typically require tearing across the entire top, which may be preferable for products that need to be squeezed out or applied directly. This user experience dimension often proves decisive when companies select between formats for new product launches.

Sachet Applications Across Industries

Understanding what are sachets in practice requires examining their diverse applications across multiple sectors. These versatile packaging solutions have become essential in various industries due to their convenience, portion control capabilities, and preservation benefits.

Food Industry: Condiments, Spices, and Single-Serve Packs

The food sector represents one of the largest markets for sachet packaging applications. From fast-food condiments to premium coffee and tea products, sachets have revolutionized portion control and freshness preservation in food service and retail environments.

How Sachets Revolutionized Food Service

Sachets have transformed food distribution by enabling precise portioning while maintaining product integrity. For spices and seasonings, sachets prevent moisture ingress and flavor loss. Single-serve coffee and beverage mixes benefit from the hermetic sealing that preserves product potency until the moment of consumption.

Cosmetics: Samples, Travel-Sized Creams, and Masks

In the beauty and personal care industry, sachet applications in cosmetics and food packaging enable brands to provide trial sizes and travel-friendly options. This approach reduces consumer risk when trying new products while creating opportunities for brands to showcase their offerings.

Sample Marketing and Consumer Acquisition

Cosmetic sachets serve as powerful marketing tools, allowing consumers to experience products before committing to full-size purchases. Face masks, serums, and hair treatments particularly benefit from single-use packaging that preserves active ingredients and prevents contamination through repeated opening and closing.

| Industry | Primary Sachet Applications | Key Requirements | Market Growth Rate |

|---|---|---|---|

| Food & Beverage | Condiments, Seasonings, Instant Beverages | Food-grade materials, Moisture barriers | 8-10% annually |

| Cosmetics | Samples, Face Masks, Travel Sizes | Product compatibility, Premium appearance | 12-15% annually |

| Pharmaceuticals | OTC Medications, Powders, Granules | Child resistance, Tamper evidence | 7-9% annually |

| Household | Detergents, Cleaners, Fabric Care | Chemical resistance, Easy dispensing | 5-7% annually |

Pharmaceuticals: Powdered Medications and Single Doses

The pharmaceutical industry relies heavily on sachets for precise dosing and protection of sensitive medications. What industries commonly use sachets? Pharmaceuticals rank among the most demanding, requiring packaging that meets stringent regulatory standards while ensuring product efficacy.

Compliance and Safety in Pharmaceutical Packaging

Pharmaceutical sachets must maintain product stability throughout shelf life while featuring child-resistant properties when required. The precise dosing enabled by sachets improves medication adherence, particularly for pediatric and geriatric patients who may struggle with traditional packaging formats.

Emerging Trends: Eco-Friendly Sachets and Sampling Strategies

As sustainability concerns grow, the packaging industry is responding with innovations in eco-friendly sachet benefits that maintain functionality while reducing environmental impact. Biodegradable films and recyclable structures are emerging as viable alternatives to traditional multi-layer sachets.

Digital Integration and Smart Packaging

Modern sachets increasingly incorporate QR codes and NFC technology, transforming simple packaging into interactive marketing channels. These smart features enable brands to deliver product information, authentication details, and complementary content that enhances consumer engagement and builds brand loyalty.

When sourcing sachet packaging machinery, manufacturers across industries prioritize suppliers like SpackMachine that offer specialized equipment tailored to diverse product requirements. Their machines, designed for chemical, medical, and food applications, ensure compliance with industry-specific standards while maintaining production efficiency.

Choosing Sachets for Your Packaging Strategy

When determining what are sachets best suited for your product line, strategic considerations around cost, functionality, and market positioning become essential. Implementing sachets in your packaging strategy requires careful evaluation of several factors to ensure optimal product protection and consumer experience.

Key Benefits: Convenience, Cost, and Shelf Life

The primary sachet benefits that drive their adoption across industries include their exceptional convenience, cost-effectiveness, and ability to extend product shelf life. These lightweight, portion-controlled packages reduce waste while providing significant logistical advantages.

Quantifiable Advantages for Business Operations

From a business perspective, sachets deliver measurable benefits across the supply chain. The reduced weight compared to bottles or jars translates to lower shipping costs. Their compact nature optimizes warehouse space utilization, while their flexibility in production runs allows businesses to scale operations efficiently in response to market demand.

| Benefit Category | Sachet Advantage | Business Impact | Consumer Value |

|---|---|---|---|

| Convenience | Portable, single-use format | Increased usage occasions | On-the-go consumption |

| Cost Efficiency | Lower material usage per unit | Reduced production costs | Affordable trial options |

| Product Protection | Hermetic sealing technology | Extended shelf life | Preserved freshness |

| Market Penetration | Low entry-point pricing | Expanded market reach | Reduced purchase barrier |

| Sustainability | Minimized material volume | Reduced environmental footprint | Less household waste |

Sourcing Suppliers: What to Look for in Quality and Reliability

Selecting the right partner for small packet packaging significantly impacts product quality and operational efficiency. Key supplier evaluation criteria should include manufacturing capabilities, quality control processes, and compliance with relevant industry standards.

Critical Supplier Assessment Criteria

Beyond basic manufacturing capabilities, evaluate potential suppliers on their technical expertise and support services. Companies like SpackMachine offer end-to-end solutions from machinery to ongoing technical support, which proves invaluable for businesses new to sachet packaging. Certification standards (CE, FDA) and quality management systems indicate suppliers committed to consistent quality and regulatory compliance.

Decision Factors: When to Choose Sachets Over Stick Packs

Understanding how do sachets compare to stick packs enables informed decision-making based on product characteristics and market requirements. While both formats offer single-use convenience, their suitability varies based on content type, dispensing needs, and brand positioning.

Product-Specific Considerations

Sachets generally excel with semi-viscous products and when maximum branding area is desired. Stick packs offer advantages for powdered products requiring precision pouring. Production volume projections should influence format selection, as each requires different machinery investments and operational considerations.

Getting Started: Practical Steps for New Brands

For companies exploring the benefits of sachet packaging for businesses, a methodical approach ensures successful implementation. Begin with small production runs to test market response before scaling. Many suppliers offer pilot programs or small-batch production options specifically designed for market entry.

Implementation Timeline and Considerations

A typical sachet packaging implementation involves multiple phases, from initial concept and material selection to production trials and full-scale launch. Working with experienced partners can streamline this process, particularly for brands without prior packaging expertise. Consider factors like filling accuracy requirements, seal integrity testing, and quality control procedures when establishing your production protocols.

By carefully evaluating these factors, businesses can successfully integrate sachets into their packaging strategy, creating opportunities for product innovation, market expansion, and enhanced consumer experiences.

Conclusion

From their humble origins as scented pouches to today’s high-tech single-use wonders, sachets have proven their worth across industries like food, cosmetics, and pharmaceuticals. What are sachets? They’re versatile, compact solutions that deliver convenience, precision, and freshness—whether it’s a ketchup packet or a skincare sample. Their evolution reflects a blend of innovative materials and smart design, offering businesses a powerful tool to meet consumer demands while optimizing production.

As Leon Liu, Technical Sales Manager at SpackMachine, I’ve seen firsthand how our cutting-edge machinery brings these benefits to life for brands worldwide. With a Mechatronics background and a decade in packaging, I’m proud to work with SpackMachine—a leader in delivering reliable, tailored solutions. Takeaway: embrace sachets to elevate your packaging strategy and stay ahead in a competitive market.

FAQ

Q1: What is a sachet?

A1: A sachet is a small, sealed packet typically used to contain a single serving or dose of a product, commonly made from laminated film or plastic.

Q2: What are the common uses of sachets?

A2: Sachets are widely used in packaging food, cosmetics, pharmaceuticals, and other consumer goods by providing single-use, portion-controlled doses.

Q3: How are sachets produced?

A3: They are usually produced using vertical form fill seal (VFFS) machines that form, fill, and seal the sachets in one continuous process.

Q4: What materials are typically used to make sachets?

A4: Sachets are most often made from laminated films, various plastics, or paper, which protect contents and maintain product integrity.

Q5: What advantages do sachets offer in packaging?

A5: Sachets provide benefits like convenience, precise dosing, extended shelf life, and cost-effective, lightweight packaging solutions.

Q6: How do sachets differ from stick packs?

A6: While both are single-use packages, sachets are typically flat and rectangular, whereas stick packs are narrow and cylindrical, each designed for different product applications.

Q7: Are sachets environmentally friendly?

A7: Many sachets are designed to be lightweight and some use biodegradable materials; however, their environmental impact depends on the materials and recycling options available.

Q8: Where can I find more detailed information about sachet packaging?

A8: Authoritative guides, industry reports, and case studies from experienced packaging companies offer detailed insights into sachet design and benefits.

External Links

- What Exactly Is Sachet? A Complete Guide

- What Is a Sachet? – Universal Pack

- Stick Pack vs Sachet: What’s the Difference? – IPharmachine

- Sachet Packaging Material – assemco

- Plastic sachets: As big brands cashed in, a waste crisis spiraled

- 9 Uses for Single-Use Sachets – American FlexPack, Inc.

- What is a SACHET, how is it made, and what can it contain?

- What Is Sachet? Everything You Need To Know – HonorPack

0 Comments