As a professional in the packaging arena, I’ve had the pleasure of working with various types of machinery, and tea bag packing machines hold a special place in this field. These machines streamline the packaging process for tea, ensuring that every cup of your favorite brew is wrapped perfectly. This article will guide you through the essential components, functionality, and considerations for selecting the right tea bag packing machine.

What Makes Tea Bag Packing Machines Essential?

Tea bag packing machines are essential in ensuring that tea remains fresh and appealing, all while operating at highly efficient speeds. From my experience, the operation of these machines is a meticulous dance of technology and design, tailored specifically for the tea industry. They are engineered to create both inner and outer packaging—think of it as a protective hug for the delicate leaves inside. The inner bags are crafted to preserve flavor and aroma, while the outer packaging presents the tea in an attractive manner that catches the eye of consumers.

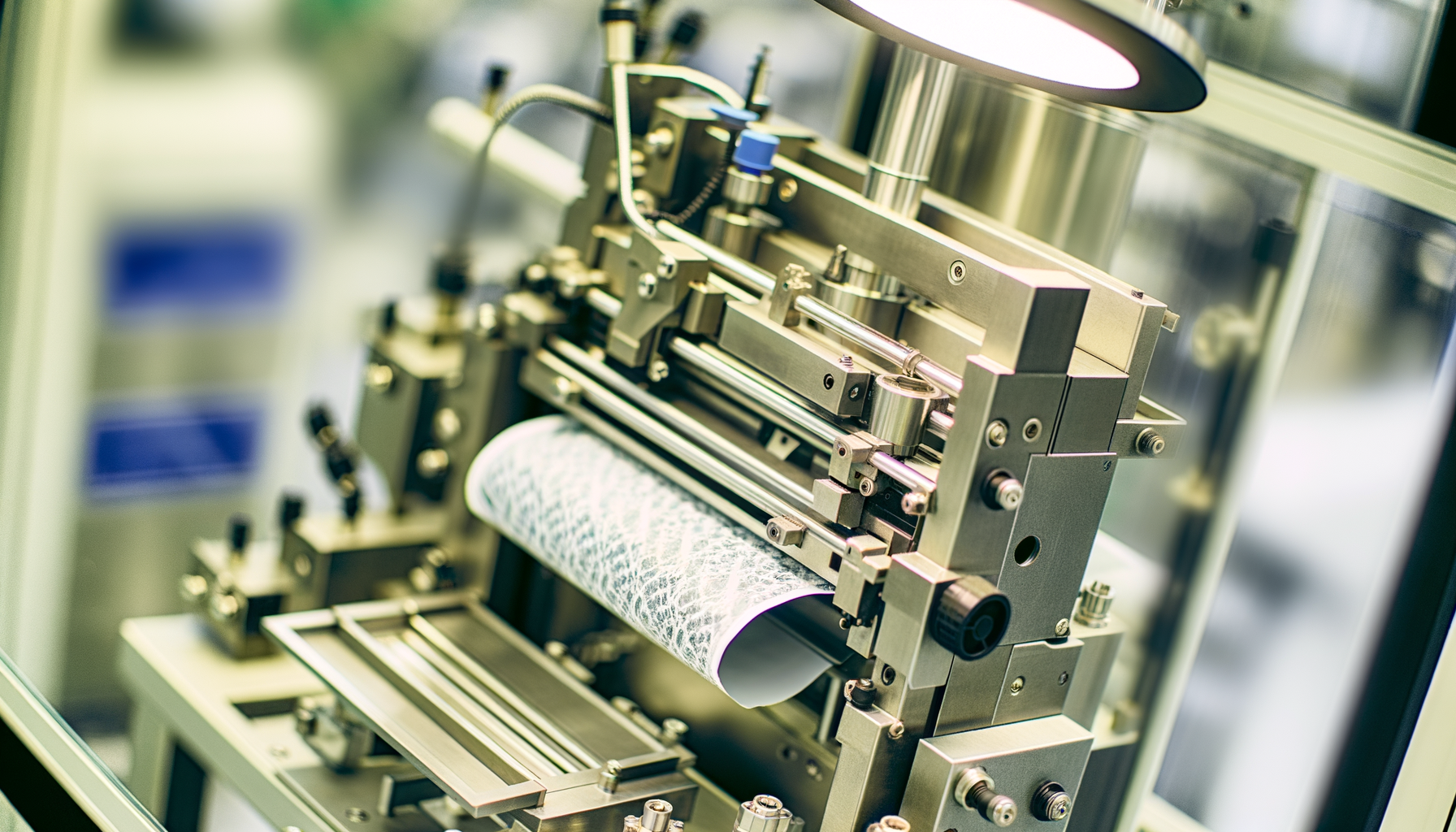

What I find most fascinating yet practical is how the machines manage multiple functionalities simultaneously. By utilizing various roll positions, the machinery can automate the preparation of bag films and efficiently handle tags and strings—all while minimizing human error. This integration not only makes packing faster but also significantly boosts accuracy, reducing the chances of producing subpar products. In fact, research shows that implementing automated packing processes can enhance production rates by as much as 50%. That’s not just a number; it equates to increased profit margins and improved consistency in product quality.

Moreover, the flexibility of modern tea bag packing machines allows producers to cater to diverse market preferences without sacrificing efficiency. By employing one machine to create a variety of bag types, companies can respond swiftly to consumer trends. This adaptability is important in the highly competitive tea industry, where the ability to deliver high-quality products rapidly can be a game changer. It’s a blend of precision engineering and a deep understanding of the product that makes these machines invaluable in today’s tea market.

How Do Different Types of Tea Bags Influence Machine Selection?

Understanding the impact of different types of tea bags is crucial for anyone looking to invest in tea bag packing machines. Various designs, such as pyramid bags and 3-side seal bags, require distinct machine features optimized for production efficiency. From my experience, this variation in bag design is not just about aesthetics; it significantly influences brewing performance and customer satisfaction.

For instance, pyramid tea bags are often appreciated for their ability to enhance the infusion process. The unique shape allows tea leaves to move freely within the bag, providing more surface area for water interaction. In contrast, traditional flat tea bags may not facilitate the same level of diffusion. Consequently, when selecting a packing machine, it’s essential to consider whether it can accommodate both designs without compromising quality or efficiency.

The flexibility of a packing machine to produce various bag shapes translates into a competitive edge. In my observations, brands that can quickly shift production lines to cater to trends in bag design often experience higher consumer engagement. Here’s a quick look at key features to consider based on bag types:

| Bag Type | Features Needed |

|---|---|

| Pyramid Bags | Advanced sealing technology, adjustable size settings, enhanced material handling |

| 3-Side Seal Bags | Standard sealing mechanisms, efficient film feeding system |

Investing in the right machinery that accommodates diverse tea bag shapes can lead to improved flavor extraction and customer delight. So, as you weigh your options, remember that the right bag design isn’t just a trend; it’s a strategic move to boost your brand’s presence in an increasingly competitive market.

What Automation Features Should You Look For?

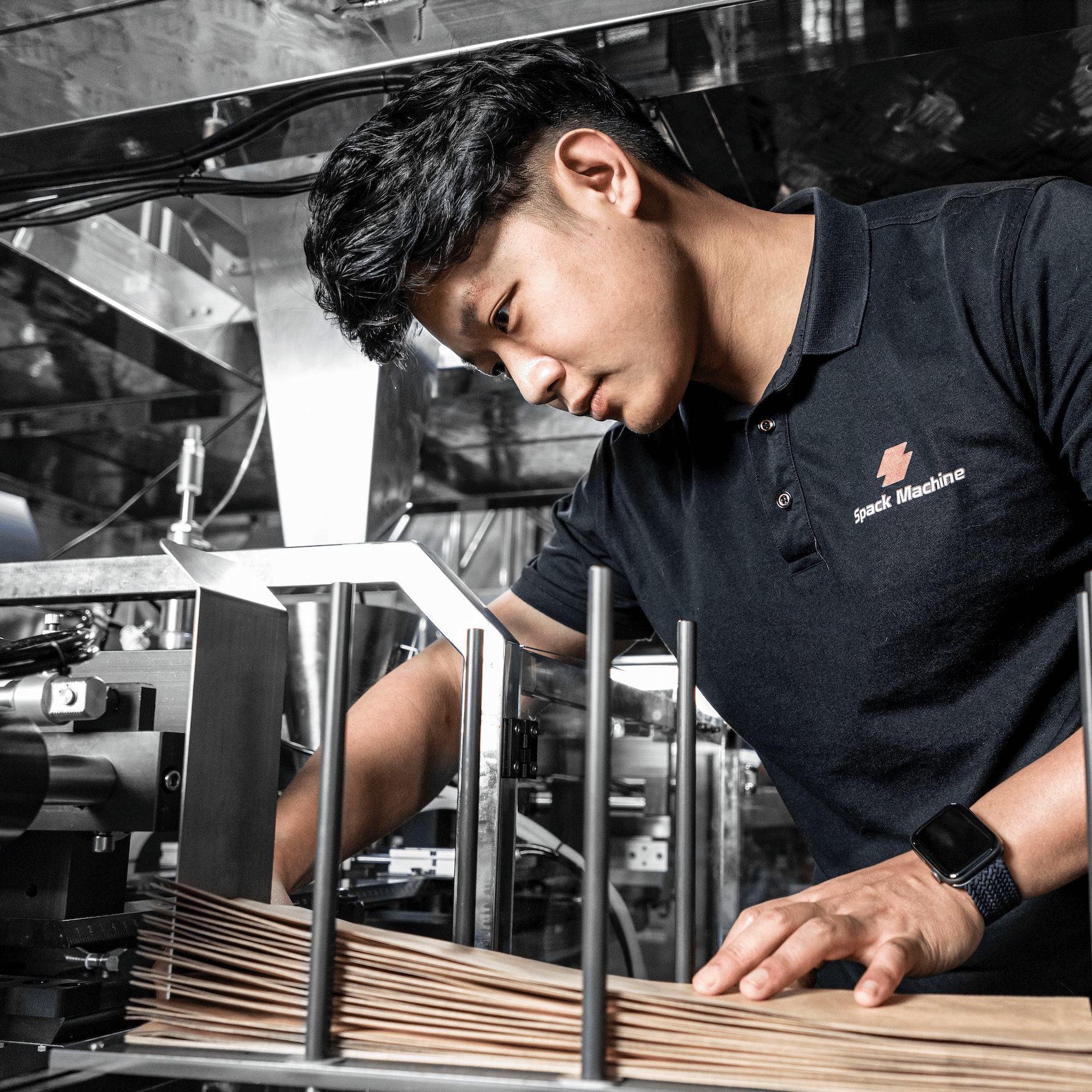

Automation is a game changer in tea bag packing. The more automated a machine is, the less human intervention is needed, which not only reduces errors but also speeds up production. Investing in automated features can significantly enhance packing speed, accuracy, and overall operational efficiency. In my experience, machines equipped with mechanical arms to transfer inner sachets into outer bags are particularly effective. Automation not only saves time but also minimizes the risk of cross-contamination, ensuring that every tea bag is as fresh as possible when it reaches the consumer. Automated packing solutions can improve efficiency by 30-40%, benefiting both small and large-scale operations.

One of the most impressive automation features I’ve encountered is the integration of advanced sensors and controls. These allow real-time monitoring of the packing process, adjusting parameters on-the-fly to maintain optimal packing conditions. For instance, if the machine detects a misalignment or a variation in bag weight, it can automatically stop the line, allowing for quick corrections without affecting overall production.

Furthermore, robotic arms don’t just look cool in action; they can handle intricate tasks with precision. The ability of these machines to accurately place tea bags into outer packaging reduces the chance of damage and increases throughput. It’s like having a super-efficient assembly line worker that never gets tired or distracted!

Beyond speed and accuracy, automation can also pave the way for scalability. As your production needs grow, upgrading or adding automated features becomes a breeze, allowing you to keep pace with market demands without a complete overhaul of your system. This flexibility can be a game changer for businesses aiming to expand their reach while maintaining product quality.

In summary, when considering a tea bag packing machine, don’t underestimate the power of automation. It not only boosts efficiency and speed but also enhances product integrity—critical factors in today’s competitive tea market.

How Can Customization Impact Your Production Needs?

Customization options for tea bag packing machines are invaluable for producers looking to tailor their packaging to specific market needs or branding requirements. From my extensive experience in the industry, I’ve seen how specialized bag sizes, unique designs, and branding elements can help set a product apart in a crowded market. Personalized packaging isn’t just a trend; it’s a powerful tool that captivates consumers and drives their purchasing decisions.

A machine that allows for customization enables producers to adapt to different tea types or brands with ease. This flexibility is vital in a fast-paced market, where consumers’ preferences can shift rapidly. For example, if a new herbal tea suddenly gains popularity, a producer can adjust the machine settings to accommodate the different bag size or packaging design that appeals to that target audience. Ingeniously, a customizable packing machine can even allow for limited-time offers or seasonal designs, creating a buzz around the product and encouraging impulse purchases.

Moreover, customized packaging can significantly boost brand loyalty and sales. When consumers recognize a distinctive product identity, they are more likely to return for the same brand, knowing it appeals to their tastes. In fact, studies have shown that well-executed, unique packaging design can increase sales by up to 30%. This means that investing in a packing machine with customization capabilities is not just about aesthetics; it’s about driving business growth.

Ultimately, a tea bag packing machine that prioritizes customization can help producers stay ahead of market trends and connect with consumers in ways that enhance their brand image. It’s a win-win for everyone involved, and just like a good cup of tea, the right blend of features can lead to delightful results.

What Maintenance and Support Options Are Critical?

Regular maintenance and robust technical support are non-negotiable for any machinery investment, especially for tea bag packing machines that see frequent use. These machines are the unsung heroes of the tea industry, working tirelessly to ensure that your favorite blends are packaged efficiently and consistently. In my experience, keeping these machines well-maintained is essential for prolonging their lifespan and minimizing downtime due to unexpected hiccups.

Imagine a scenario where your machine has suddenly decided to take an unplanned vacation right during peak production hours. This is where regular maintenance steps in like a superhero. Implementing routine checks and adhering to the manufacturer’s maintenance schedule can help spot issues before they escalate into more significant problems. From checking for any wear and tear on components to ensuring the machine functions smoothly, these simple steps can save you headaches down the line.

However, let’s not underestimate the importance of effective technical support. In my professional journey, I’ve learned that having access to a responsive customer support team can be just as crucial as the machine’s capabilities. The ability to troubleshoot and resolve issues swiftly is essential to maintaining a smooth production flow. Machines that come with clear maintenance protocols and robust support provide peace of mind, particularly when those inevitable problems arise. A quick call to an expert can often mean the difference between a minor bump on the road and a full-blown production disaster.

In summary, investing in a tea bag packing machine is not purely about its features and capabilities; it encompasses a commitment to regular maintenance and a solid support network. After all, a well-maintained machine is a happy machine, and a happy machine leads to a more fruitful production experience.

Conclusions

Tea bag packing machines are pivotal for any tea-producing business looking to enhance quality, efficiency, and customer appeal. By understanding the specific features and capabilities of these machines, you can make informed decisions that set your business apart in a competitive market.

External Links Recommendation

0 Comments